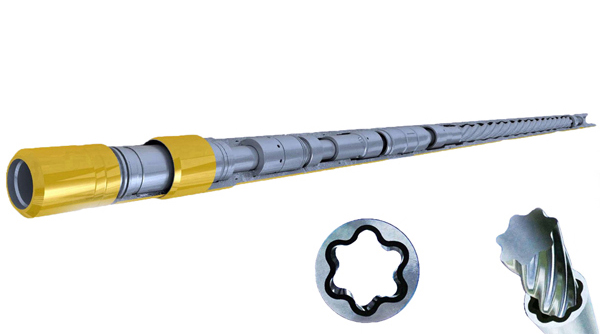

- High TEMP PDM

High Temperature Long Service Life Downhole Motor

High Temperature Long Service Life Downhole Motor Principle

The physical properties of the stator rubber have been improved by using

Compared with ordinary nitrile rubber, HNBR has improved oil resistance,

At the same time, the rubber vulcanization method has been optimized to improve

The amount of fillers has been adjusted to increase

And quality plasticizers have been added to

The optimization of various methods in the rubber formula has significantly improve the temperature and medium resistance level, performance, and lifespan of the stator rubber.

Optimizing the rubber formulas has greatly improved the temperature and impurity resistance levels, resulting in better performance and a longer service life.

Optimization for Service Life

Radial Bearings: Ceramic materials are used to increase hardness and toughness

Centralizer: Wear-resistant belts are embedded in PDC composite.

Bending Shell: Wear-resistant belt of anti-cracking layer is made of wear-resistant

Rotor: Special manufacturing process is adopted to prevent pinholes from occurring during chrome plating.